News & Insights

Cryogenic Valves Are Powering a Zero-Emission Future Cryogenic Valves Are Powering a Zero-Emission Future...

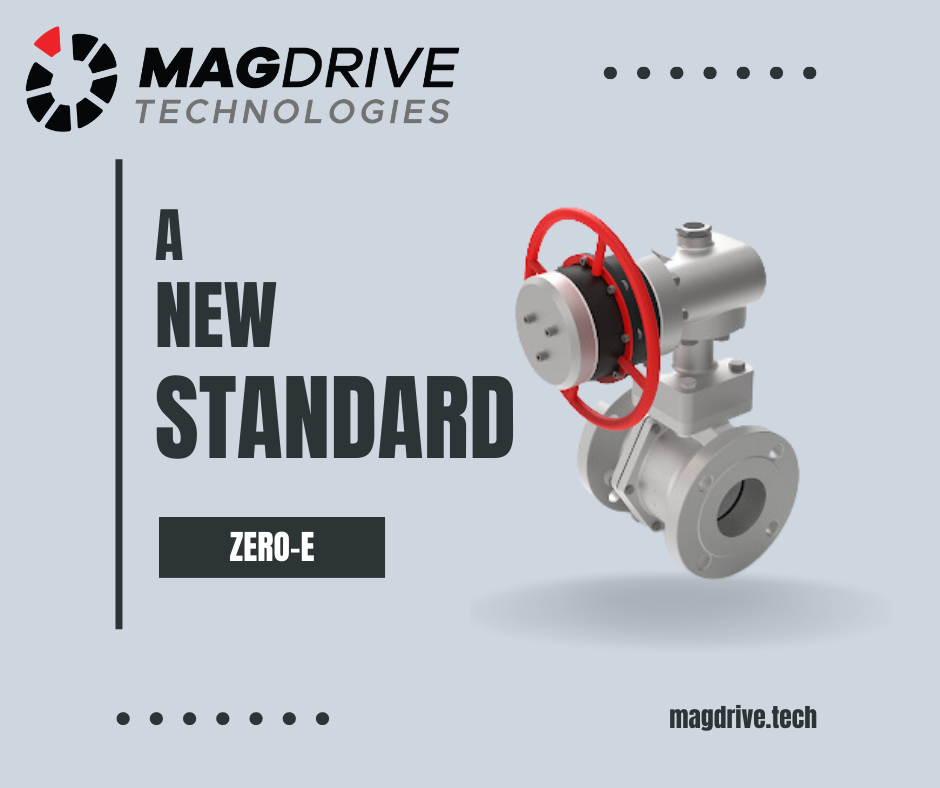

The E-Drive aims to deliver zero-emission cryogenic valve operation, enabling precise flow control, miniaturization,...

Magnetically Actuated Valves in Hydrogen Storage and Transportation A Solution to Leaking Hydrogen Valves?...

MagDrive Partners with Williams Valve Corp to Introduce Industry’s First Magnetically Actuated Zero-Emission...

The Benefits of Magnetically Actuated Valves in Aerospace The aerospace industry thrives on cutting-edge...

The False Choice between Methane Fees and Energy Production America Can Lead on Methane Emissions While...

Partner with MagDrive for Zero-Emission Valve Solutions Become a MagDrive Partner Today Discover how...

Valves in Space Returning to Earth Solving Valve Leaks for Space Exploration Valves play a pivotal role...

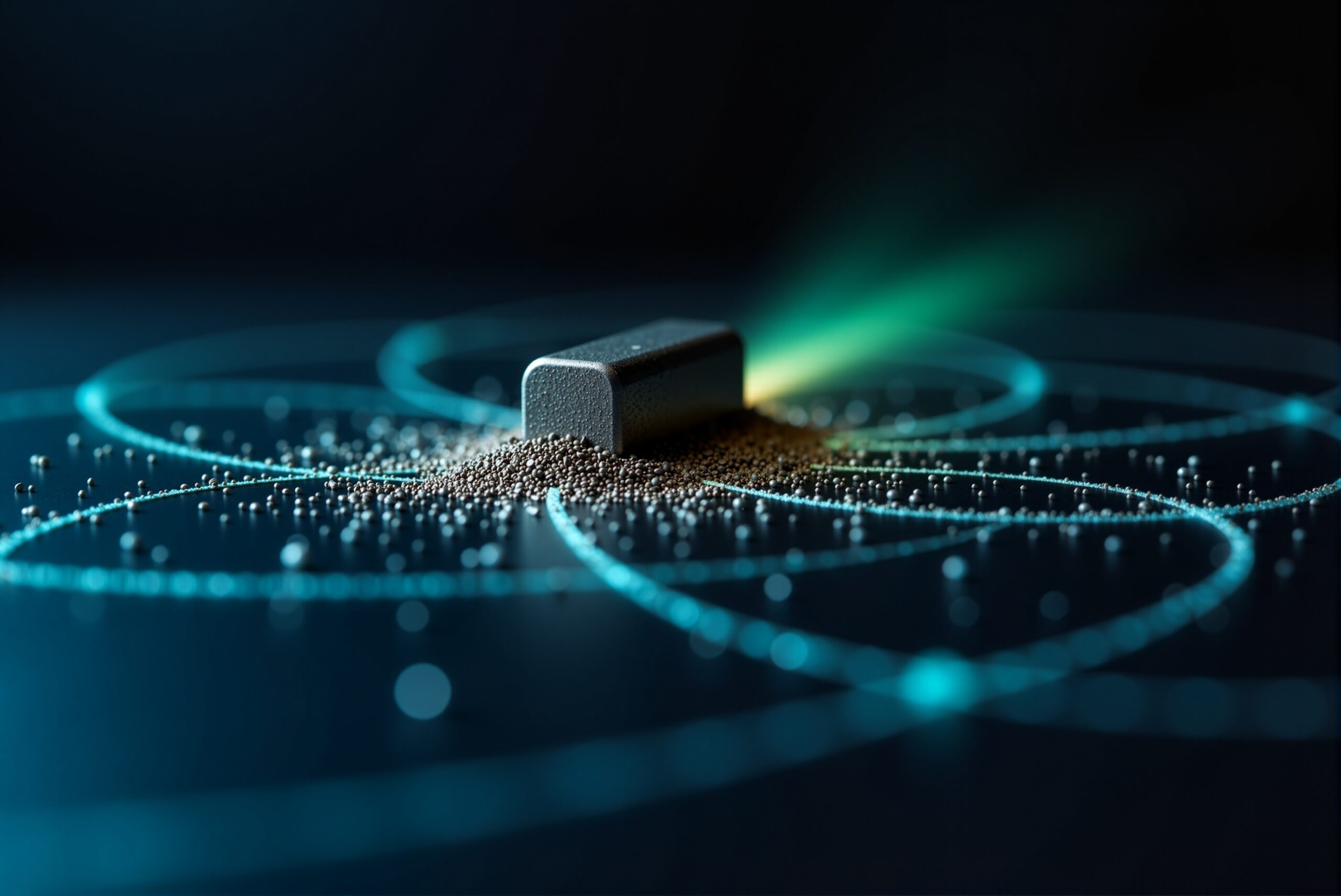

MagDrive Technologies: Eliminating Fugitive Emissions at the Source The Problem In the oil and gas sector,...

No posts found