Industry

Validation

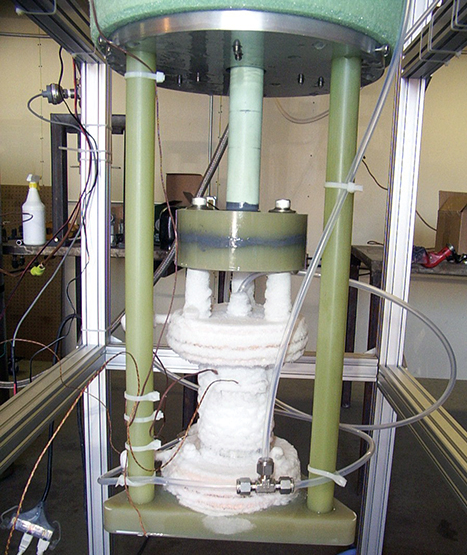

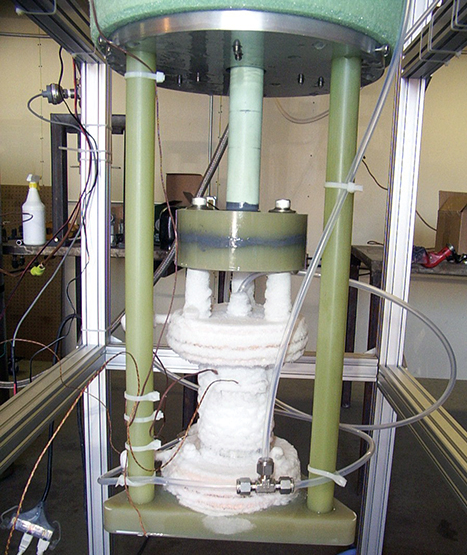

MagDrive cryogenic valves have been tested and approved in NASA SBIR programs, confirming durability and leak-free performance in the most extreme environments.

Problem/Challenge in the Sector

Liquefied natural gas (LNG) and cryogenic applications demand valve performance at extreme low temperatures, often approaching -300°F. Standard seals and actuation mechanisms fail under thermal contraction, leading to leaks, safety issues, and costly downtime.

Why MagDrive Solves It Better

Leaking valves during LNG transport can result in significant product loss resulting in damage to profits and the environment. Magnetic actuation eliminates stem packing failures, while advanced materials maintain integrity. MagDrive ensures reliable operation, reduction of lost product, and the elimination of methane emissions from valve stems.

Industry

Validation

MagDrive cryogenic valves have been tested and approved in NASA SBIR programs, confirming durability and leak-free performance in the most extreme environments.

Technical Specifications

Cryogenic

performance

Proven at -300°F in NASA testing

API 6FA

certified

Passed 1,800°F fire test with zero leaks

Solid-wall

stem seal

Eliminates leak paths under thermal stress

High torque

capability

Operates any valve type in cryogenic or LNG service